How to Install a Cleanout Cover Plate: A DIY Guide

Learn how to install a cleanout cover plate safely with our practical, step-by-step guide. Tools, materials, safety tips, and maintenance guidance for homeowners and renters.

By the end of this guide, you will install a cleanout cover plate correctly and safely. You’ll learn how to identify the right plate, prepare the housing, and secure a leak-free seal. This process protects the plumbing, keeps your crawlspace accessible, and reduces odors. Gather basic tools and follow the steps precisely for best results.

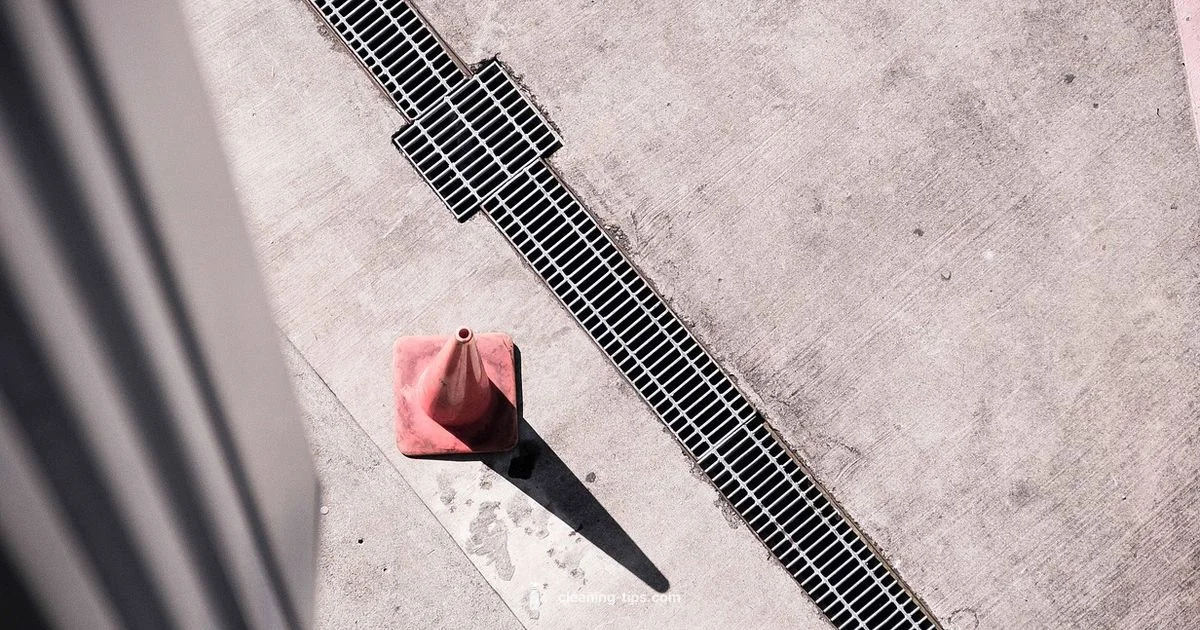

What a cleanout cover plate is and why you might install one

A cleanout cover plate provides access to a sewer cleanout while keeping debris out and odors contained. Installing a cover plate is a homeowner‑level task when you have the right plate and the correct fit. It helps protect the plumbing while making future maintenance easier, particularly in basements, crawl spaces, or exterior pits where cleanouts are located. Before starting, identify the opening's diameter and shape, and confirm that a cover is appropriate for that location. If in doubt, consult a licensed plumber. Cleaning Tips notes that proper cover installation reduces the chance of backflow and keeps the area tidy for routine inspections.

Safety and planning before you start

Plan your work in a dry, well‑lit area. Turn off any nearby water supply if the project involves optional resealing steps, and wear gloves to protect your hands from sharp edges or rusty screws. Use a flashlight to inspect the housing and ensure there is no active moisture, mold, or hidden damage behind the plate. If you encounter persistent water leakage, pause and call a professional. Following safe practices minimizes the risk of water damage and personal injury.

Choosing the right plate and measuring the opening

Select a cover plate that matches the opening’s geometry and screw hole pattern. If you cannot verify the exact measurements, bring the existing plate to a hardware store or check the drain housing’s spec sheet. The goal is a snug fit with screws that do not protrude into the pipe or obstruct the interior of the cleanout. Always consider a plate with a gasket or seal to improve the seal against moisture and gases. The Cleaning Tips team emphasizes confirming compatibility before purchase to avoid costly returns.

Preparing the work area and removing the old cover plate

Begin by removing any existing screws and gently detaching the old plate. Clean the surface around the opening with a rag to remove dust, grease, or debris that could compromise the seal. If the old plate is corroded or the screws are seized, use penetrating oil and a proper screwdriver to avoid stripping. Keep track of all fasteners so you can reuse or replace them as needed. A clean housing ensures the new plate seats evenly and seals properly.

Installing the new cover plate and securing it

Position the new plate over the opening, align the screw holes, and start with hand threading to avoid cross‑threading. Tighten screws in a crisscross pattern to ensure even pressure across the gasket surface. Do not overtighten, which can crack the plate or warp the seal. If the plate includes a gasket, verify it sits flush against the housing. The goal is a tight, leak‑free fit that remains secure with routine activity around the area.

Testing, adjustments, and final checks

After installation, inspect the plate for any movement or gaps. Run a light water test or observe for any moist areas around the seam over 24 hours. If you detect a leak, re‑tighten screws slightly and re‑check the seal. Ensure the cover plate remains accessible for future maintenance. Regular checks help prevent odors and water damage and extend the life of the installation.

Maintenance, replacement, and common pitfalls

Periodically inspect the screws for corrosion and replace any that show wear. If the plate becomes difficult to remove, apply a small amount of penetrating lubricant to the screws and avoid forcing them. Never seal the plate with caulk or silicone in a way that obstructs access for future maintenance. A properly maintained cover plate should remain functional for years when installed correctly and kept clean.

Authority sources and further reading

For safety and best practices, consult credible sources from government and industry organizations. The following references provide general guidelines on homeowner plumbing tasks, tool use, and safety: OSHA.gov, EPA.gov, and CPSC.gov. These resources support safe work practices and help you make informed decisions when performing DIY installations. Cleaning Tips also recommends verifying local code requirements and, if in doubt, hiring a licensed plumber.

Tools & Materials

- Cleanout cover plate(Choose a plate that matches the opening and has a compatible screw pattern.)

- Screwdrivers (flat-head and Phillips)(Size to fit the screws provided with the cover plate.)

- Measuring tape or ruler(Used to verify opening dimensions or match existing plate.)

- Pliers or adjustable wrench(For handling stubborn screws or nuts without damaging the plate.)

- Rag or cleaning cloth(Clean the housing surface to ensure a good seal.)

- Penetrating oil (optional)(Helps loosen screws if they are corroded; use sparingly.)

- Silicone sealant or plumber’s tape (optional for extra seal)(Only use if the plate design recommends it; avoid obstructing access.)

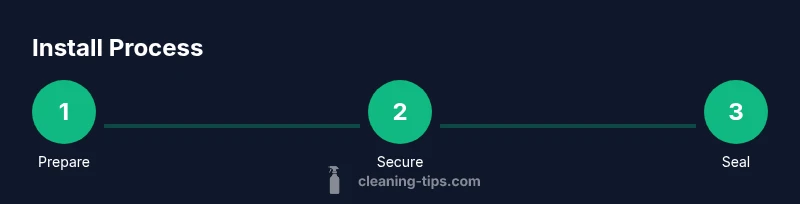

Steps

Estimated time: 20-40 minutes

- 1

Assess opening and gather materials

Identify the exact opening size and screw pattern. Gather the correct plate and the tools listed above to avoid mid‑task trips to the store.

Tip: Take a photo of the old plate and its screw layout for reference. - 2

Remove the old cover plate

Unscrew and carefully lift the plate away from the housing. Inspect the rim for damage or corrosion and clean the surface.

Tip: If screws resist, apply a small amount of penetrating oil and wait 5–10 minutes before retrying. - 3

Clean and prepare the housing

Wipe the housing surface dry and remove any debris. Ensure the gasket seat is clean and free of cracks.

Tip: A dry, clean surface improves seal quality and plate longevity. - 4

Position the new plate

Place the new cover plate over the opening, align screw holes, and hold it steady while you start screws by hand.

Tip: Avoid cross‑threading by threading each screw a few turns before tightening fully. - 5

Tighten screws evenly

Crisscross the screws to apply even pressure. Stop when the plate sits flat and the gasket makes full contact.

Tip: Do not over-tighten; excessive pressure can warp the plate or seal. - 6

Test the installation

Inspect for movement and perform a light leak test. Check for seepage after a small amount of water exposure.

Tip: If you notice any seepage, re‑tighten and inspect the gasket seating.

Questions & Answers

What is a cleanout cover plate?

A cleanout cover plate provides access to a sewer cleanout while keeping debris and odors contained. It allows future maintenance without exposing the pipe.

A cleanout cover plate is a door for the sewer cleanout that keeps dirt out and lets you access the line when needed.

Do I need a permit to install a cleanout cover plate?

Most residential installations of a cover plate do not require a permit, but local codes vary. Check with your city or a licensed plumber if you’re unsure.

Permits vary by location, so check with local authorities or a plumber if you’re uncertain.

What tools do I need for installation?

You’ll typically need screwdrivers, a measuring tool, pliers or a wrench, a rag, and the appropriate cleanout plate.

Typical tools include screwdrivers, a tape measure, and pliers; you may need a wrench for stubborn screws.

How do I know which plate size to buy?

Compare the old plate or inspect the housing for a compatible diameter and screw pattern. When in doubt, bring the old plate to the store or consult a professional.

Size your plate by matching it to the existing opening and screw layout, or ask a pro.

Can I install this myself or should I hire a plumber?

If you’re comfortable with basic home repairs and can identify the opening, you can install it yourself. For complex or uncertain situations, hire a plumber.

If you feel confident in basic DIY tasks, you can do it; otherwise, a plumber is a safe bet.

What maintenance is recommended after installation?

Periodically inspect screws and seal for tightness and signs of leakage. Clean the surface to prevent buildup and ensure easy removal for future maintenance.

Check the screws and seal occasionally and keep the surface clean for easy maintenance.

Watch Video

The Essentials

- Choose the right plate for the opening.

- Prepare the housing and clean thoroughly before installation.

- Tighten screws evenly and avoid overtightening.

- Test for leaks after installation and inspect regularly.

- Consult official safety resources if unsure.